About the petroleum products: Carbon residue and ash content of lubricating oils

The residual carbon of oil products means that the oil products are placed in the residual carbon side setting instrument, which is heated to evaporate and decompose under the test condition that is not accessible to the air. When the steam is exhausted, the remaining black residue in the instrument is the residual carbon, which is expressed as the percentage of the mass.

Residual carbon is used as an index for refining degree in the specification of lubricating oil, which is of great significance for guiding production. The amount of residual carbon in lubricating oil is related to the chemical composition and refining degree of lubricating oil. The crude oil containing many colloidal substances is more carbon. The distillates of the same crude oil are different with the refining and refining depth of different methods, the amount of residual carbon in the product is different, the refining depth is large, the content of the heavy aromatic hydrocarbon and the gum in the product is reduced, and the residue of the product is also reduced.

The main substances to form carbon residue in the lubricating oil are colloid, asphaltene and polycyclic aromatic hydrocarbons. They are easily decomposed and condensed into residual carbon under the condition of insufficient air, and therefore, the residue is used to check the degree of refining in the production of lubricating oil.

In the production, we should not only determine the products with carbon residue specifications, but also check the semi finished products. In addition, residual carbon is also determined for coking feedstock, which is used to estimate coke production. The more carbon residue is, the higher the yield of coke.

Carbon residue was used as an indicator of carbon deposition in engine use in the early period, but it was later proved that the tendency to form carbon accumulation was not related to the residual carbon of the lubricating oil.

The coking tendency in reciprocating steam turbines can be approximately expressed by residual carbon in cylinder oil. Because cylinder oil may be decomposed by heat in steam engines, such as carbon residue, coking tends to be larger.

At present, in the specifications of petroleum products, except for a part of the lubricating oil which stipulates residual carbon, there are 10% residual carbon in the light diesel oil specification.

2. Ash

Ash refers to the residue of inorganic matter which has been charred after the carbonization of the sample under the specified conditions, and is expressed in terms of mass percent.

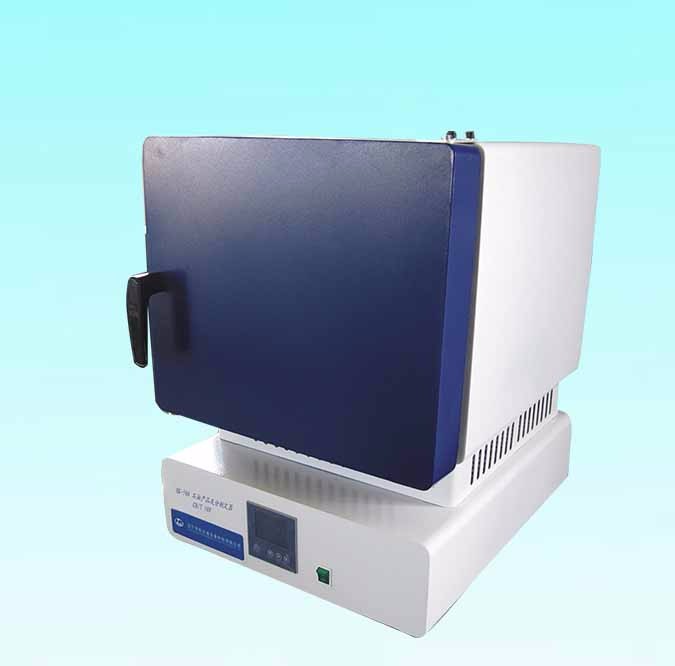

The ash side determination method is carried out by GB/T508 (YT-508 ash measuring instrument). The test oil is burned with ash free filter paper as the ignition core, and then the solid residue is repeatedly burned at the temperature of (755. 25) C, and after cooling, it is weighed to the constant weight. Then it is calculated as a mass percentage.

The ash content of petroleum products contains CaO, MgO, Fe2O3, siO2, V2O5 and Na2O. These oxides are formed by decomposition or oxidation of salts at high temperatures.

The sources of ash in petroleum products are as follows: one is the soluble mineral salt from crude oil, which remains in heavy residue when distilled; two is mixed in the process of refining, for example, the metal salts (such as sodium sulfate, sodium carbonate, etc.) produced in the refining of acid and alkali are not removed, or the pure white soil particles are not filtered in the treatment of white soil; The three is the metal compounds produced by the corrosion of the equipment in the process of refining (especially acid and alkali refining) and storage and transportation; four is a metal salt additive added to improve the quality of the lubricating oil, such as some dispersing agent, anti oxygen and anti-corrosion additive, etc. When lubricating oil is used, it will also increase the ash content due to metal corrosion and dust pollution.

The ash content of side fixed petroleum products has different meanings for different oil products.

Ash content is used as an indicator of the degree of refining for the non additive lubricating oil, jet fuel, diesel fuel oil and so on. The ash content is higher, such as the residue of metal salt or clay in the refining. Therefore, ash is not greater than a certain quantity in specifications. For example, jet lubricants require ash not greater than 0.005%.

For some lubricating oils containing metallic salt additives, the ash content is not more than a certain value before adding additives, and the ash content is not less than the other after adding the additive. Before adding additives, the ash content should be few to ensure proper refining degree. The ash after adding additives is used to ensure that there are enough additives to meet the quality requirements of lubricating oil.